As a professional manufacturer on casting parts, Fluido provides to customers perfect solutions on the metal industry. We focus on providing services and quality beyond customers' expectations at a very competitive price.

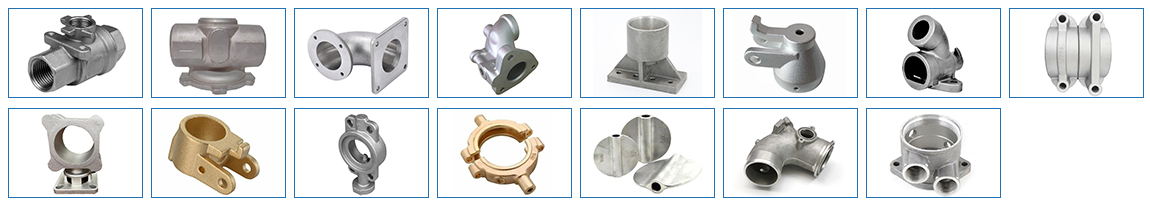

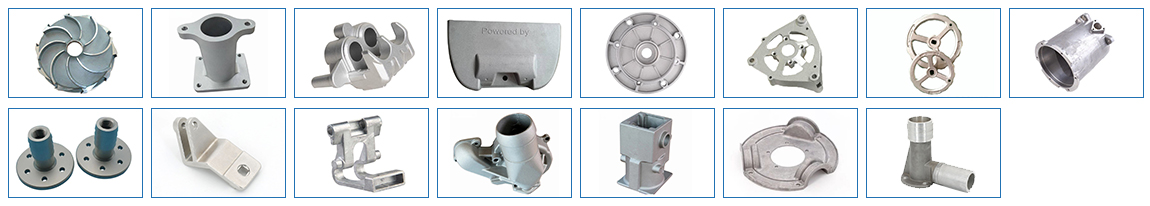

Our main products are valves and OEM casting parts. And the technologies are like Sand Casting, Investment Casting, Die Casting, Lost Foam Casting, and Permanent Casting. Until now, our products have been sold globally through more than 30 countries/regions.

Our knowledge on the casting area enables us to design, produce, machine, assembly then give out complete products. We'll review your needs and provide creative solutions to reduce costs and to achieve excellent operations just like you are pursuing. And the information, samples and drawings you can provide will help us make correct supply to meet your special requirements. Welcome to contact us and start win -win cooperation.

Casting process can be subdivided into Sand Casting, Investment Casting, Die Casting, Lost Foam Casting and Permanent Casting, which are widely used in the production of valves, accounting for more than 80% of the customized valves we receive, the main application of casting products is for low and medium pressure pipelines.The material is cast iron, cast steel and cast stainless steel.

Qingdao Fluido not only supplies finished valves, but also provides various cast valve bodies, valve covers, and valve plates according to customer drawings or requirements. The weight ranges from 0.5kgs to 200kgs, and materials include gray iron, ductile iron, cast steel, and stainless steel. We welcome your inquiry.

Welding is a process that joins two or more pieces of metal together by melting and fusing them. In valves and pipe fittings, the Welding process is often co-existing with the Stamping process.

Forging is a manufacturing process where metal is shaped and formed using compressive forces. It involves heating the metal and then applying pressure to shape it into the desired form. High pressure valves are required to use the forging process.

Machining is a manufacturing process that involves the use of various tools and machines to shape and finish a material into a desired shape or size. This process includes the most common thread machining in valves, valve plate sealing surface machining, and flange sealing surface machining.

Stamping is a manufacturing process in which a flat sheet of metal is formed into a desired shape using a press machine and a die. It is commonly used in industries for producing various components and parts with high precision and efficiency. Valve holders as well as other accessories are stamped processes.

Production Process Introduction

Sand Casting is divided into three types: Green sand casting, Resin sand casting and Precoated sand casting. Green Sand Casting is the method with the lowest cost, but its surface smoothness is not good. Resin Sand Casting can give good surface and accuracy size, so it is widely used in the casting industry. Precoated Sand Casting can give surface roughness of RA = 6.3 ~ 12.5 μm and size accuracy of CT7 ~ CT9 level, which is mainly used to make cast steel parts. FLUIDO mainly do the casting on Grey Iron, Ductile Iron, Stainless Steel, Carbon steel, aluminum and Brass. Unit weight ranges from 0.3kg to 80kg.

Investment Casting is considered as a relatively expensive process in a long period of time. However, compared with other replacement process which requires many welding or machining processes, the investment-casting process can usually significantly reduce the production cost of the overall parts. Fluido will use two investment-casting methods to meet customer's quality requirements: Water Glass and Silicon Glue. The surface quality of the Water Glass is not as good as the surface made by Silicon Glue, however its cost is lower. Silicon Glue gives out good surface however its cost is high. Anyway Fluido will choose the most economical method based on customers' tolerance requirements and product use. Unit Weight Ranges from 20G to 15kgs.

Die Casting is a metal casting process, which is characterized by pressing the melting metal into the mold cavity under high pressure. Compared with the sand casting and refined casting process, the advantage of die casting is that it can give out shape-complicated parts with thin wall thickness, the surface can be up to CT6-8, the quality of the casting is high, the strength and hardness are higher than the sand casting, the productivity is high, the cost is low, and it is easy to achieve automated production. The disadvantage is that the mold fee is high and it is not suitable for production of small batches. During the die -casting process, as the metal liquid is filled with a high speed, the casting is prone to small pores, so it is not suitable for thick wall thickness parts. Die casting is generally used to make aluminum and zinc alloy parts.

Lost Foam Casting (LFC) is similar to the investment casting, also is an evaporation model casting process, but its model is plastic foam instead of wax. This technology uses the low boiling point of the plastic foam to simplify the investment casting process without needing to melt the wax from the mold. Fluido only uses the Lost Foam Casting process to produce ductile iron pipe fittings and large -size valve body parts.

Permanent Casting is a casting method that pour liquid metal into metal casting to obtain casting parts. The model is made of heat -resistant alloy steel metal, which can be used repeatedly. The parts produced by Permanent Casting are not only good in size's accuracy and surface's smoothness, but also has higher strength than Sand Casting, just the disadvantage is that the mold fee is high. Fluido only uses the Permanent Casting process to produce aluminum alloy casting parts and zinc alloy casting parts.

RELATED PRODUCTS

In addition to casting, we can also provide stamping, machining and forging, and we always select the most suitable process according to customer drawings and samples.

TESTING

In order to ensure that our casting and forging parts always meet the highest standard, we provide professional and reliable testing service to our clients. We can do those tests in-house, or we can commission authoritative third parties to carry out the tests, such as SGS,BV,TUV etc. We can send samples to the third party for testing or the third party can come to the workshop for on-site inspection. Inspection reports are always provided before shipment

1.Chemical composition analysis: To ensure the chemical composition to meet the standard, we do chemical composition analysis for every single batch of products, and provide authoritative reports to our clients. Test bars are also available for our clients to test if asked.

2.Mechanical property test: To ensure the mechanical property to meet the standard, we do mechanical property test for every single batch of products, and provide authoritative test reports to our clients. Test bars are also available for our clients to test if asked.

3.Other Tests: We can do other tests according to customers' requirements, such as leakage test, galvanized surface salt spray test, bursting test, etc., to ensure the highest quality and to avoid any failures as required by customers.

INSPECTION

No matter how excellent the quality of our casting and forging parts as we advertise, inspection is the only way to prove our reliable quality. Rely on advanced inspection facilities and professional quality assurance team, Fluido casting strives to supply our customers 100% qualified casting and forging products. Inspection from customers or a third party is also welcomed.

PACKING

Packing is easily overlooked by many of our competitors, but Fluido Casting sees packing as a critical element in the whole production process, since proper packing ensures our high-quality aluminum casting products are delivered to our customers safely and efficiently. Every single batch of our products delivered to customers is well packed by our experienced packing team. Our packing covers carton box, wooden box, wooden pallet, steel pallet, plastic pallet, etc.

FAQ

CUSTOMER CASE

All the OEM casting and forging part photos on the website are just to show our manufacturing capabilities and product range. We can design and manufacture OEM metal part according to different needs of customers. We believe that more than 20 years of professional experience to provide you with the best service.

DOWNLOAD ![]() oem pdf catalogue.pdf

oem pdf catalogue.pdf