Valve body material selection and each material introduction

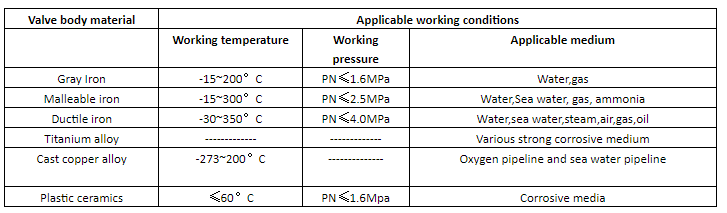

Cast iron is the least costly of these materials and is widely used in live and industrial piping due to its low price. The working pressure and high temperature resistance of cast iron valve body is poor, so it is usually only used in low temperature and low pressure pipes. Like diesel, seawater and acidic media pipeline must be replaced with other materials.

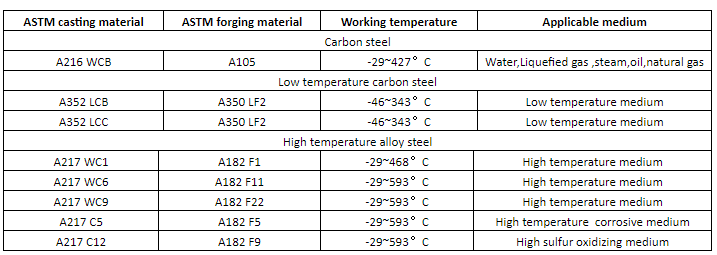

Carbon steel as the valve body material, with high working pressure strength and corrosion resistance, while the cost is lower than stainless steel. Carbon steel valves are widely used in high temperature and high pressure pipelines.

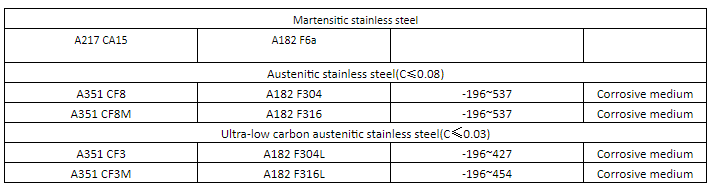

Stainless steel as the valve body material, with excellent corrosion resistance and high temperature performance, while the mechanical strength and sealing performance than cast iron material, but the cost is higher than cast iron and carbon steel material, processing intensity than carbon steel material.

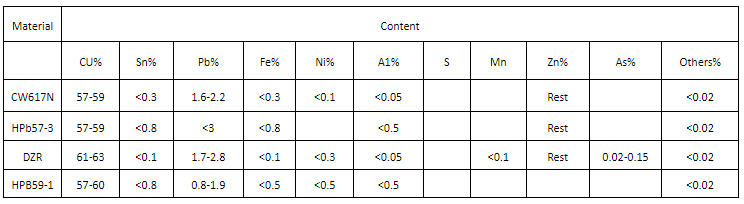

Brass as the valve body material has the advantages of strong corrosion resistance, good thermal conductivity, good processing performance. But the disadvantages are also obvious: brass material toughness is poor, easy to break; brass material melting point is low, not suitale for high temperature and high pressure working environment; high price, higher or equal to the price of stainless steel material.

The choice of valve body material depends on the working environment of the pipeline and cost factors.Qingdao Fluido summary of the valve body material applicable media and working temperature, if you have any valve question or inquiry list please contact us, we will give the fastest answer:

Cast Iron

Carbon Steel

Stainless Steel

Brass or bronze