Products

Underground Fully Welded Steel Ball Valve

Underground buried fully welded ball valve technical parameter

Size: NPS 4"~~NPS 6o",

Pressure class: CL150~~CL2500

Design standard: APl 6D

Length of structure:API 6D

For product beyond the scope ofthe standard, it shall be manufactured by specifications in manufacturers standard or users requirements.

Flange connecting end : ASME B16.5/ASME B16.47

Butt welding connecting end : ASME B16.25/ASME B31.8

Wall thickness: ASME B16.34

Fire safe test: API 6O7IAPl 6FA

Inspection and test: API 6D

Pressure and temperature rating: ASME B16.34

Main body material:A105、LF2、F304、F316、F304L、F316L、F51,etc.

Ball valve seat materialt.PTFE、RPTFE、NYLON、DEVLON、Derlin、PEEK、PPL、HNBR、FKM or metal hard seal etc.

Drive device:handle, worm wheel, electric, pneumatic, pneumatic- hydraulic, electro-hydraulic, etc.

Product Details

1. The pressure parts and control parts are forged, and the parts are of higher quality.

2. Automatic welding assembly is adopted between each section of the ball valve body to make the valve body stronger, safe and reliable without leakage.

3. Directly buried welding ball valve can be directly buried in the ground, without the need to build a valve well, the operating mechanism and discharge port, grease port are led to the ground, does not affect the operation and maintenance can greatly save construction costs and construction time.

4. Welding connection is adopted for ball valve and pipeline, which is safe and reliable and eliminates the risk of leakage of flange connection.

5. Trunnion mounted ball valve, piston seat, flexible operation, reliable sealing.

6. Anti-static function, and comply with API 607 fire protection requirements.

7. Fully welded ball valve with grease injection auxiliary sealing device.

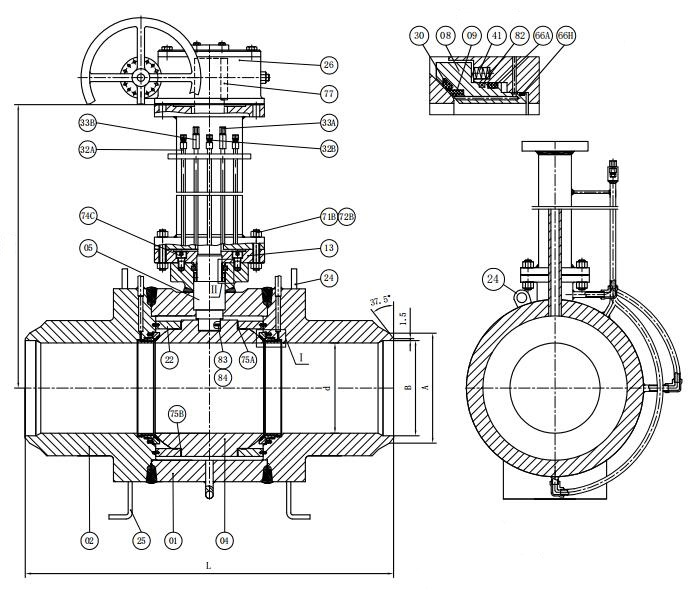

Underground buried fully welded ball valve structure

Underground buried fully welded ball valve design optional

END CONNECTIONS

RF, RTJ as per B16.5 &B16.47

BW, Butt Welded as per B16.25

BODY DESIGN

Forged welded two-piece and three-piece

SEAT DESIGN

Soft or metal seated with hard facing on Ball and Seats

Self relieving seats

Double piston seats

STRUCTURE

Double block and bleed design (DBB)

Secondary seals in pure Graphite

Anti-static device

Anti-blowout stem

Emergency sealant injection on seats and stem available

Low fugitive emission stem packing available

CRA overlay on all dynamic sealing areas or on all wetted parts available

Stem extension for underground installations

OPERATOR

Manual: wrench or gear with padlocking

Actuated: Pneumatic/ Hydraulic/Electric