Products

Rubber Lined Dual Plate Check Valve ANSI150 PN10 PN16 JIS10K

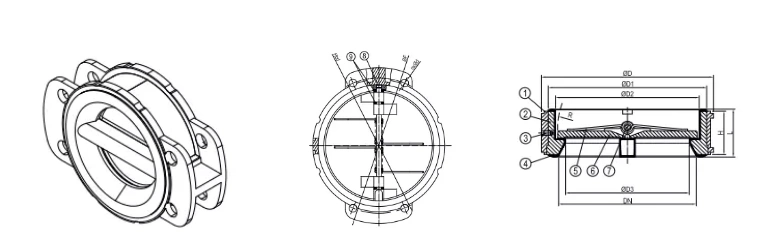

Description: Wafer type with mounting loops, NBR or EPDM lined nodular cast iron body, spring tensioned dual check valve with soft sealing AlBr plates.

Application: Food,beverage industry; Chemcal, petrochemical industries; Water and wastewater technology; Shipbuilding; Power plants ; Pulp and paper industries. Preventing backflow in water, sea water and oil systems etc.

Product Details

The valve is made of flexible rubber material and is designed to allow flow in one direction while preventing backflow or reverse flow. It consists of a conical or flat rubber sleeve or flaps that act as a one-way door. When the pressure on the upstream side of the valve is greater than the pressure on the downstream side, the valve opens, allowing fluid or gas to flow through. When the pressure on the downstream side becomes greater than the upstream side, the valve closes, preventing backflow.

Rubber line check valves are often used in various industries, including wastewater treatment, sewage systems, drainage systems, irrigation systems, and industrial piping systems. They are preferred in applications where a tight seal is required, as the rubber material provides excellent sealing properties.

These valves are typically easy to install and require minimal maintenance. However, it is important to select the appropriate size and material of the valve based on the specific application requirements.

| NO. | Part | Material | Code |

| 1 | Alignment Body | Nodular Cast Iron | GGG40.3 |

| 2 | Insert Body | Nodular Cast Iron | GGG40.3 |

| 3 | Set Screw | Steel | - |

| 4 | Liner | NBR/EPDM | - |

| 5 | Spring | Stainless Steel | SS304/SS316 |

| 6 | Plate | Aluminium Bronze alloy | C954 |

| 7 | Shaft | Stainless Steel | SS316 |

| 8 | Shaft Plug | Stainless Steel | SS316 |

| 9 | Thrust Washer | Teflon | - |

| Size | A | B | C | D | E | F(PN10/PN16) | G(PN10/PN16) | H | 」 | K | Weight(kg |

| DN50 | 159 | 101 | 84.8 | 66.7 | 50 | 125 | 18 | 28.5 | 47.6 | 54 | 2.27 |

| DN65 | 179 | 120 | 99 | 79.4 | 50 | 145 | 18 | 36.5 | 58.7 | 54 | 2.72 |

| DN80 | 200 | 133 | 116 | 92.1 | 50 | 160 | 18 | 41.3 | 69.9 | 54 | 3.63 |

| DN100 | 220 | 171 | 143 | 118 | 60 | 180 | 18 | 54 | 87.3 | 63.5 | 6.81 |

| DN125 | 250 | 198 | 172 | 144 | 63 | 210 | 18 | 67.5 | 113 | 66.7 | 9.08 |

| DN150 | 285 | 222 | 201 | 172 | 75.5 | 240 | 22 | 80.2 | 141 | 79.4 | 11.8 |

| DN200 | 340 | 280 | 255 | 222 | 94.5 | 295 | 22 | 106 | 192 | 98.4 | 19.52 |

| DN250 | 406 | 336 | 309 | 276 | 97.5 | 350/355 | 22/26 | 130 | 230 | 102 | 26.33 |

| DN300 | 482 | 406 | 366 | 327 | 126 | 400/410 | 22/26 | 159 | 275 | 130 | 45.4 |

| DN350 | 533 | 450 | 394 | 356 | 176 | 460/470 | 22/26 | 172 | 305 | 181 | 60.29 |

| DN400 | 596 | 488 | 488 | 406 | 158 | 515/525 | 26/30 | 197 | 356 | 162 | 77.18 |

| DN450 | 635 | 545 | 506 | 460 | 180 | 565/585 | 26/30 | 222 | 406 | 184 | 99.88 |

| DN500 | 715 | 595 | 553 | 508 | 211 | 620/650 | 26/33 | 248 | 460 | 216 | 130.3 |