Products

DIN3352 Angle Bellows Seal Globe Valve Flanged Wcb PN16 PN25 PN40

DIN Angle Globe Valve

DIN cast iron angle globe valve

Face to face: DIN3202-F32

Flange drilled: DIN2532/2533

Normal pressure: PN10/16

Size: DN15-DN300

Product Details

The following are some of the typical applications of Cast lron Angle globe valves:

- Cooling water systems where flow needs to be regulated

- Fuel oil system where flow is regulated and leaktightness is of importance

- High-point vents and low-point drains when leaktightness and safety are major considerations

- Feedwater, chemical feed, condenser air extraction, and extraction drain systems

It is applicable to the cutting and connection of pipelines medium that are used in various industries such as flue gas uerification plant, gas supply pipeline, vacuum facilities, ammonia facilities, hot water, colding & freezing system, heating technology, steam system, chemical industry, pharmacy, chemical fertilizer, electric power industry etc. The nominal pressure can be fromm 1.0 Mpa to 16.0MPa and the working temperature can be reached to 350 Celsius degree.

Main Structural features

1. This product has logical strucure, reliable seal, excellent performance and nice design.

2. The seal surface is overlay welded with hard chrome ally material which is attrition resistant, corrosion ressistant, has good friction resistant and long life.

3. The stem is quenched and tempered, and its surface is treated by nitriding treatment, thus it has good corrosion resistant and friction resistant.

4. It has double seal capability, thus is more reliable for zero leakage warranty.

5. The stem show the position indicator, thus it is clearer.

Technical specification

| Structural formation | BB, BG, OS&Y |

| Driving maner | Handwheel or motor operated |

| Design standard | DIN3356 |

| Face to face | DIN3202 |

| Flange ends | DIN2543-2545 |

| Test and inspection | DIN3230 |

Products performance specification

| Nominal pressure | Shell test (MPa) | Sealing test (MPa) | Suitable temperature | Suitable medium |

| (Mpa) | ||||

| 1.6 | 2.4 | 1.76 | No more than 350oC | Water oil & gas |

| 2.5 | 3.75 | 2.75 | ||

| 4 | 6 | 4.4 | ||

| 6.4 | 9.6 | 7.04 |

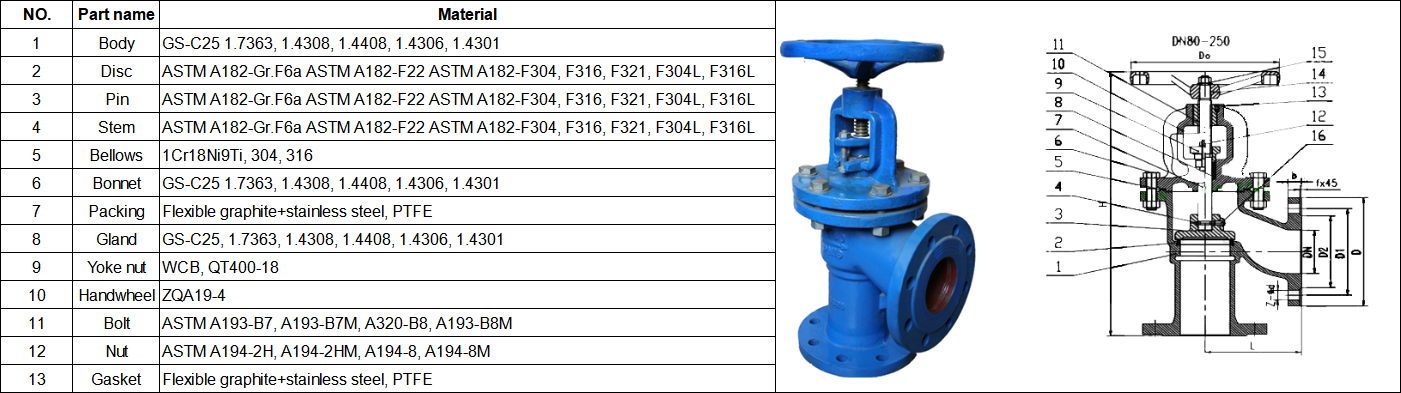

Main parts materials

Dimensions and weight for PN16 Nominal pressure

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| L | mm | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | 980 |

| H | mm | 166 | 166 | 172 | 175 | 193 | 195 | 213 | 227 | 294 | 325 | 355 | 440 | 580 | 620 | 785 |

| W | mm | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 280 | 300 | 340 | 400 | 450 | 450 | 500 | 500 |

| Weight | KG | 4 | 5 | 6 | 10 | 13 | 18 | 25 | 30 | 40 | 50 | 100 | 180 | 300 | 450 | 670 |

Dimensions and weight for PN25 Nominal pressure

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| L | mm | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | 980 |

| H | mm | 166 | 166 | 172 | 175 | 193 | 195 | 213 | 227 | 294 | 325 | 355 | 440 | 580 | 620 | 785 |

| W | mm | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 280 | 300 | 340 | 400 | 450 | 450 | 500 | 500 |

| Weight | KG | 4 | 5 | 6 | 11 | 14 | 19 | 27 | 32 | 43 | 53 | 110 | 200 | 330 | 480 | 700 |

Dimensions and weight for PN40 Nominal pressure

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| L | mm | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | 980 |

| L | mm | 166 | 166 | 172 | 175 | 193 | 195 | 213 | 227 | 294 | 325 | 355 | 440 | 580 | 620 | 785 |

| H | mm | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 280 | 300 | 340 | 400 | 450 | 450 | 500 | 500 |

| W | KG | 4 | 5 | 6 | 11 | 14 | 20 | 28 | 33 | 45 | 55 | 120 | 210 | 350 | 500 | 730 |